The main motive for a manufacturing plant will be to increase the effectiveness and efficiency of the equipment, resulting in an overall increase in productivity of the plant.

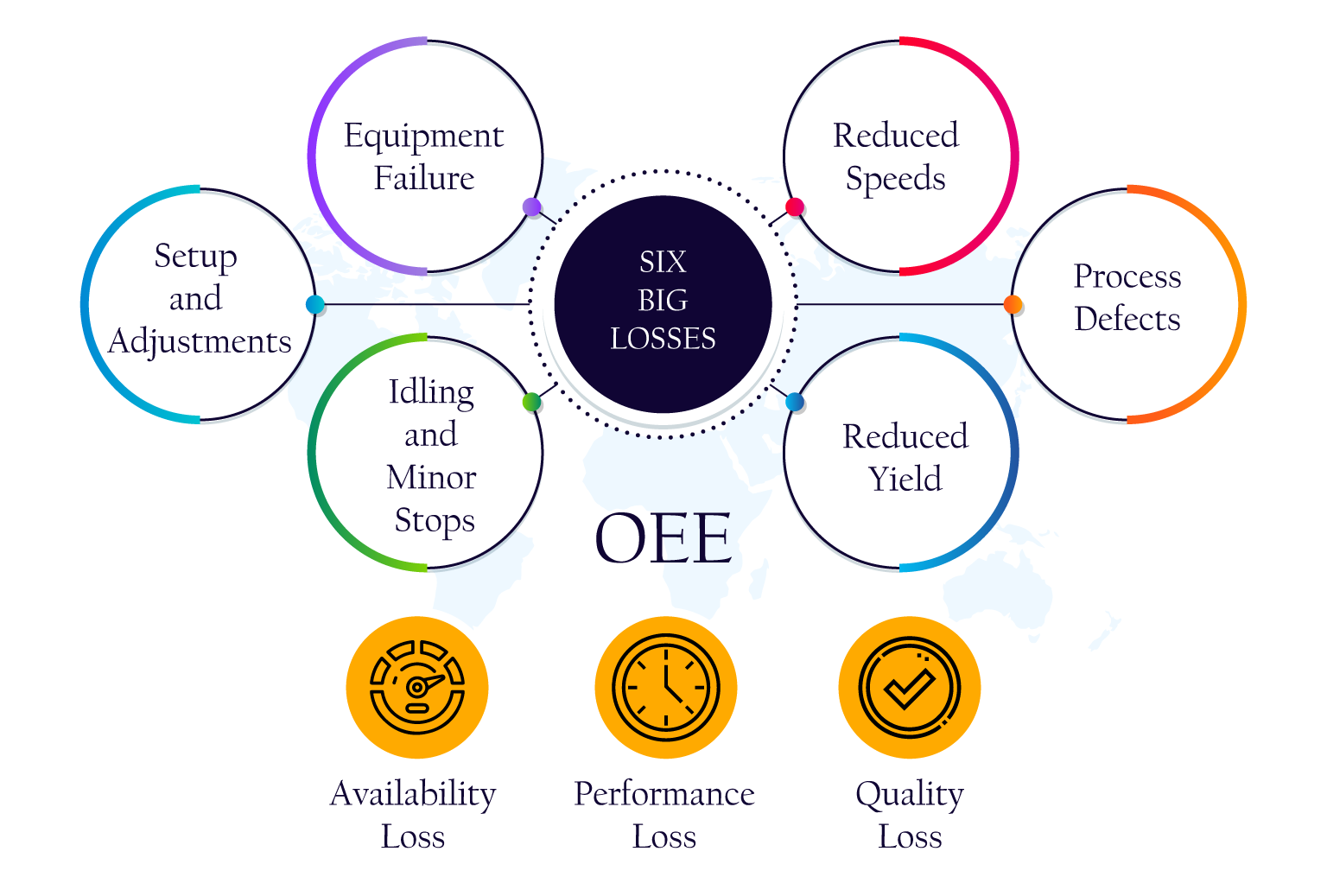

Six Big Losses in lean manufacturing is a concept to categorize productivity loss from an equipment’s perspective. It directly aligns with OEE and gives a more detailed take on the 3 OEE losses- Availability, Performance, and Quality.

OEE factors Availability, Performance, and Quality map with the 6-Big Losses of Manufacturing providing a more concrete and manageable framework to categorize your losses.

The traditional 6-Big Losses include Equipment Failure, Setup & Adjustments, Idling & Minor Stops, Reduced Speed, Process Defects, and Reduced Yield.

To make it simpler, more precise, and more consistent to be aligned with OEE losses, we can call them Unplanned Stops, Planned Stops, Small Stops, Slow Cycles, Production Rejects, and Startup Rejects.

So, if the manufacturing plants take action to address these losses, it will directly translate into the reduction of OEE losses. It will ensure a stark improvement in your OEE score, which will result in a more efficient manufacturing process.

Reach out to us to see how Kripya CenterStage Industry 4.0 solutions can help you transform your Manufacturing.