Cloud

The Cloud Cost Crisis in Manufacturing(Part 1)

In today’s fast-paced industrial landscape, standing still means falling behind. Manufacturers are under constant pressure to meet demand, reduce downtimes, and improve product quality — all while keeping costs low. That’s where real-time monitoring comes into play, and why platforms like CentralStage are transforming how factories work.

The traditional approach of periodic checks and manual data entry is no longer enough. Unexpected downtime, undetected equipment faults, and unoptimized machine usage can cost companies thousands — if not more — each year.

By implementing CentralStage’s smart shopfloor digitization, manufacturers can:

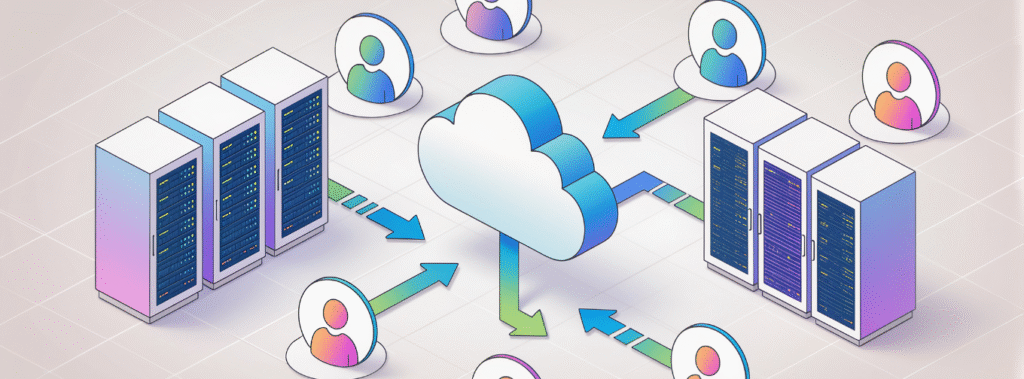

CentralStage seamlessly captures data from any machine — new or legacy — and transforms it into clear, actionable insights via a cloud-based dashboard. Imagine a dashboard that updates you if equipment efficiency drops by even 5%, or if a production line is falling behind its daily target. That’s the kind of dynamic advantage real-time monitoring brings.

“We saw a 20% improvement in line efficiency in just two months after deploying CentralStage.” — A leading automotive parts supplier

By enabling better visibility and faster response times, CentralStage helps plants run smoother, smarter, and more efficiently.

Explore how CentralStage can revolutionize your production floor:

🔗 https://www.kripya.com

The Cloud Cost Crisis in Manufacturing(Part 1)

The $300M Integration Imperative: Solving the Hardware-Software Paradox in 2026 SDVs

SaaS or Surface: The ROI of Cloud-Native PLM for the Agile Tier-1 Supplier

Range is a Design Problem: The Physics of AI-Driven Generative Design for EVs

Why Manufacturing IT Is Moving to Cloud Native Architectures

Digital Immunity: Mastering UN R155/R156 with a PLM-Driven Security Posture

Connect with us to schedule a demo or explore how CentralStage® can transform your operations.

Contact with us