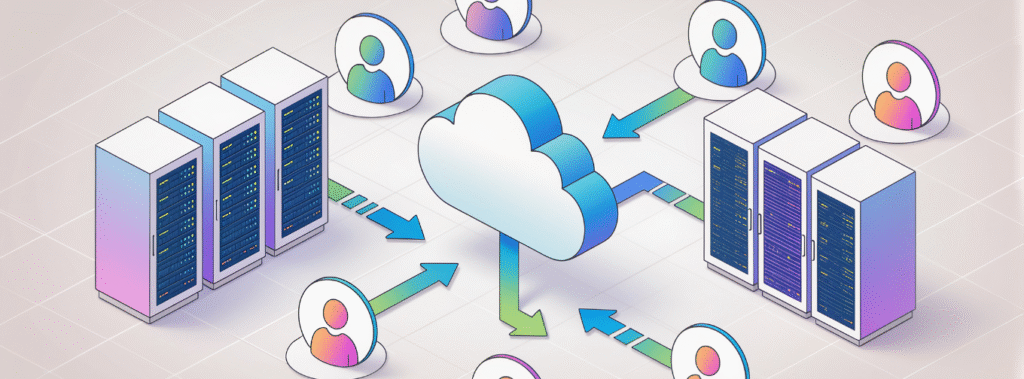

Cloud

The Cloud Cost Crisis in Manufacturing(Part 1)

The journey to Industry 4.0 doesn’t need to start with ripping and replacing your entire setup. Many manufacturers hesitate to digitize because they believe older equipment won’t fit in a smart ecosystem. That’s where CentralStage breaks barriers.

CentralStage was built for compatibility. From PLC-driven systems to analog legacy machines, the platform integrates seamlessly — capturing data and converting it into meaningful visuals.

Forget upgrading every motor or replacing entire assembly lines. CentralStage delivers all the benefits of Industry 4.0 — like reduced downtimes, better quality control, and leaner operations — without the pain of infrastructure overhaul.

“We integrated CentralStage into 15-year-old extrusion lines and achieved 12% better output in just six weeks.”

— Mid-size Plastics OEM

🔧 If your factory has older machines but modern goals, CentralStage is your bridge to the future.

The Cloud Cost Crisis in Manufacturing(Part 1)

The $300M Integration Imperative: Solving the Hardware-Software Paradox in 2026 SDVs

SaaS or Surface: The ROI of Cloud-Native PLM for the Agile Tier-1 Supplier

Range is a Design Problem: The Physics of AI-Driven Generative Design for EVs

Why Manufacturing IT Is Moving to Cloud Native Architectures

Digital Immunity: Mastering UN R155/R156 with a PLM-Driven Security Posture

Connect with us to schedule a demo or explore how CentralStage® can transform your operations.

Contact with us