Cloud

The Cloud Cost Crisis in Manufacturing(Part 1)

Imagine having the power to create precise virtual replicas of entire factories, complex machinery, or even human health parameters. With digital twin technology, this transformative capability is no longer futuristic—it’s here today.

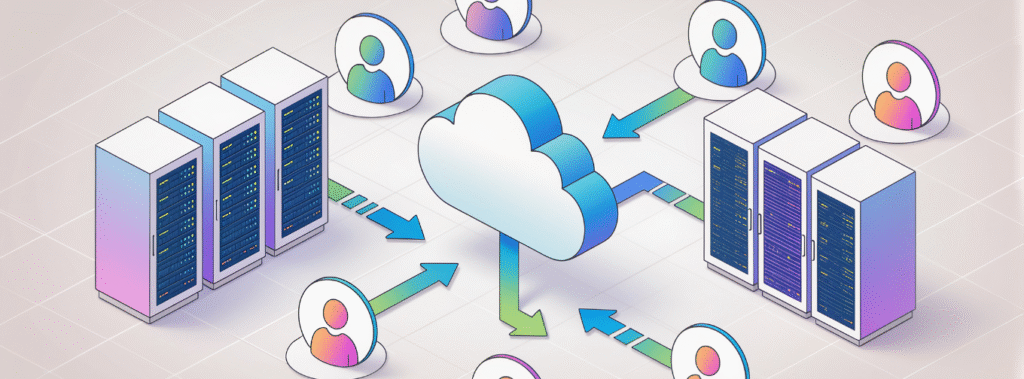

Digital twins are sophisticated digital models that mirror the physical assets they represent by continuously receiving real-time data from sensors embedded in those assets. This enables companies to monitor, simulate, and analyze performance across the entire lifecycle of a product, system, or process. From manufacturing plants to healthcare systems, digital twins provide a dynamic view that helps identify potential issues before they occur and optimizes operations for better outcomes.

The digital twin market is expanding at an extraordinary pace, with forecasts predicting it will grow at over 60% annually and reach a valuation of $73.5 billion by 2027. Industries worldwide are embracing digital twins because of the substantial advantages they offer.

The Cloud Cost Crisis in Manufacturing(Part 1)

The $300M Integration Imperative: Solving the Hardware-Software Paradox in 2026 SDVs

SaaS or Surface: The ROI of Cloud-Native PLM for the Agile Tier-1 Supplier

Range is a Design Problem: The Physics of AI-Driven Generative Design for EVs

Why Manufacturing IT Is Moving to Cloud Native Architectures

Digital Immunity: Mastering UN R155/R156 with a PLM-Driven Security Posture

Connect with us to schedule a demo or explore how CentralStage® can transform your operations.

Contact with us