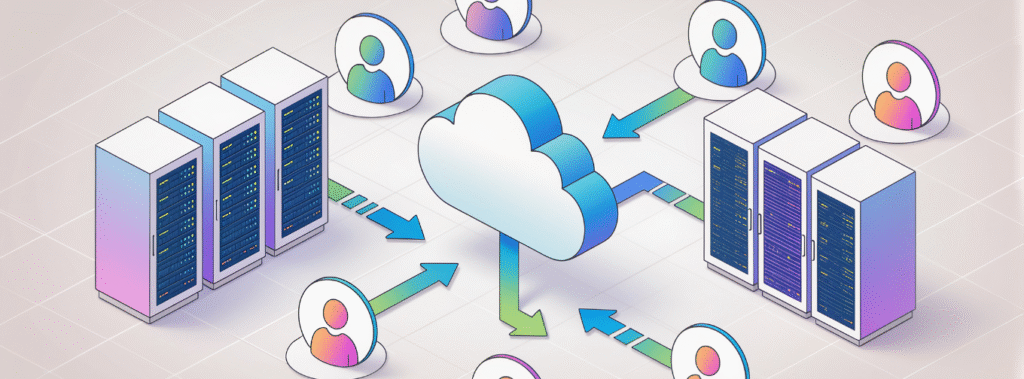

Cloud

The Cloud Cost Crisis in Manufacturing(Part 1)

In today’s fast-evolving industrial landscape, digital transformation is no longer optional—it’s essential. For discrete manufacturers, where complex product lifecycles demand efficiency, traceability, and innovation, Product Lifecycle Management (PLM) is proving to be a cornerstone of this transformation journey.

As a medium-sized organization working closely with manufacturers, we see firsthand how PLM can bridge gaps between engineering, production, and business functions. It is not just about managing CAD files or engineering changes anymore—it’s about creating a digital thread that connects every stage of a product’s lifecycle, from ideation to after-sales service.

Digital transformation in discrete manufacturing often begins with operational automation and data visibility. But the real value surfaces when data flows seamlessly across the enterprise: design informs production, production data feeds quality insights, and service loops back into R&D.

These challenges can make digital transformation feel daunting, but they also highlight the need for specialized PLM services tailored to the realities of mid-sized organizations.

Our clients often tell us that what differentiates us is our industry focus on discrete manufacturing. We understand your machines, your processes, and your pressure to deliver quality products faster at lower costs.

The organizations who thrive in the coming years will be the ones who see PLM not just as a software tool, but as a strategic enabler of digital transformation. It is about creating a connected ecosystem where engineering, manufacturing, and business leaders share the same insights and work toward the same goals.

For medium-sized organizations in the discrete manufacturing sector, the opportunity is immense. With the right PLM services partner, digital transformation doesn’t have to be overwhelming—it can be your pathway to growth, resilience, and market leadership.

👉 If your organization is looking to kickstart or accelerate its PLM journey, we’d love to connect. Our expertise lies in helping manufacturers like you turn PLM into a driver of measurable business impact.

The Cloud Cost Crisis in Manufacturing(Part 1)

The $300M Integration Imperative: Solving the Hardware-Software Paradox in 2026 SDVs

SaaS or Surface: The ROI of Cloud-Native PLM for the Agile Tier-1 Supplier

Range is a Design Problem: The Physics of AI-Driven Generative Design for EVs

Why Manufacturing IT Is Moving to Cloud Native Architectures

Digital Immunity: Mastering UN R155/R156 with a PLM-Driven Security Posture

Connect with us to schedule a demo or explore how CentralStage® can transform your operations.

Contact with us