Cloud

The Cloud Cost Crisis in Manufacturing(Part 1)

For manufacturing facilities aiming to maximize productivity and profitability, understanding and improving Overall Equipment Effectiveness (OEE) is critical. At CentralStage, we emphasize the importance of data-driven decision-making to reveal your plant’s true operational performance by measuring how long machines run, how much product they generate, and the quality of that output.

OEE consists of three key performance indicators (KPIs): Availability, Performance, and Quality—each expressed as a percentage:

This measures the actual operating time of equipment against the planned production window, excluding scheduled downtime such as maintenance. For example, if machinery is scheduled for 4 hours but experiences a 30-minute breakdown, the availability score would be 87.5%.

This KPI compares actual production output against the ideal maximum output in the same time frame. If the expected output is 25,000 units but only 22,000 were produced, the performance score is 88%.

Quality measures the ratio of finished, acceptable units to the total units started. For instance, if 10,000 units were started but only 9,000 met quality standards, the quality score is 90%.

The OEE score is the product of these three percentages. For an availability of 75%, performance of 80%, and quality of 85%, the overall OEE would be 51%.

Aiming for a perfect 100% OEE is unrealistic in real-world manufacturing conditions. Industry benchmarks suggest 85% OEE as a gold standard, achieved by top-performing factories through:

Most facilities typically score well below this, often less than half. At CentralStage, we advocate for establishing a baseline OEE measurement and striving to incrementally surpass it, recognizing that even small improvements yield significant business value.

Start by addressing unplanned downtime, the easiest KPI to improve. Leveraging real-time data on stoppage causes allows for targeted preventive maintenance. Our solutions integrate communication between operators and maintenance teams to swiftly resolve issues, minimizing production losses.

Performance issues often require deeper analysis. With advanced analytics from CentralStage’s shop floor control systems, manufacturers can identify production bottlenecks and test process adjustments to streamline workflows and boost throughput.

Focus on quality control by identifying defect trends and root causes. CentralStage’s digital solutions help optimize quality control processes and reduce defects through automated monitoring and staff training support.

Continuous, data-driven improvements across these KPIs enable manufacturers to approach world-class OEE standards over time.

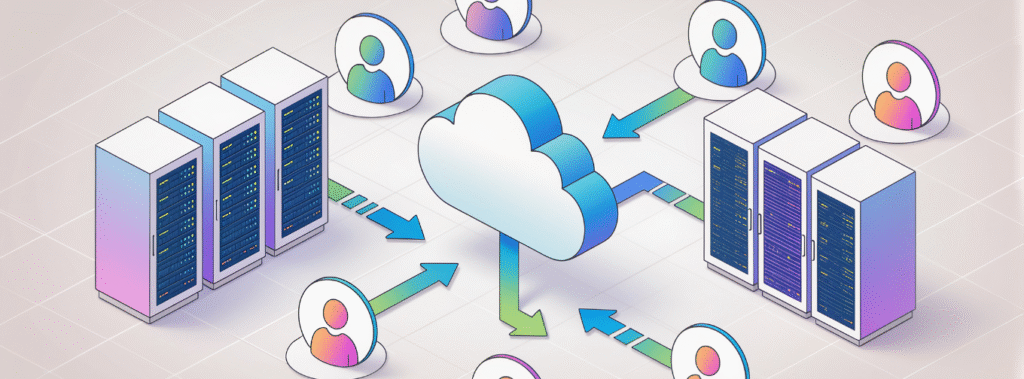

CentralStage provides powerful real-time manufacturing analytics platforms that deliver detailed, accurate, and actionable production data. Our cloud-based tools aggregate and visualize production metrics, facilitating continuous performance tracking and improvement.

Improve your plant’s OEE with intelligent data insights from CentralStage and unlock higher productivity and profitability. Contact us today to learn more and request a demo.

The Cloud Cost Crisis in Manufacturing(Part 1)

The $300M Integration Imperative: Solving the Hardware-Software Paradox in 2026 SDVs

SaaS or Surface: The ROI of Cloud-Native PLM for the Agile Tier-1 Supplier

Range is a Design Problem: The Physics of AI-Driven Generative Design for EVs

Why Manufacturing IT Is Moving to Cloud Native Architectures

Digital Immunity: Mastering UN R155/R156 with a PLM-Driven Security Posture

Connect with us to schedule a demo or explore how CentralStage® can transform your operations.

Contact with us